Method for defect-free hybrid laserarc welding of closed circumferential welds

Authors: Dr.-Ing. Sergej Gook, M. Sc. Ömer Üstündag, Dr.-Ing. Andrey Gumenyuk, Prof. Dr.-Ing. Michael Rethmeier

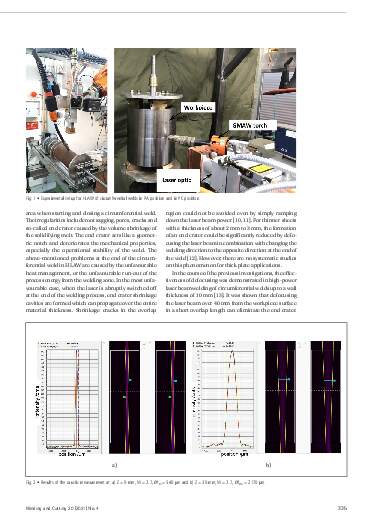

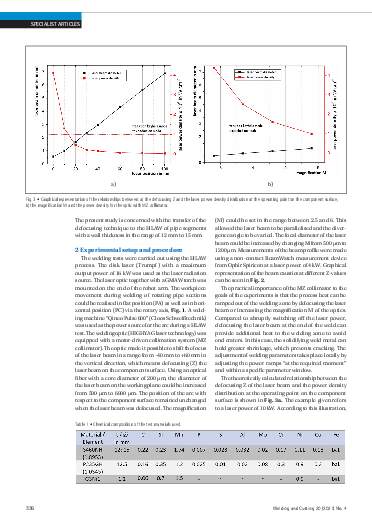

This paper presents investigation results of a process

for defect-free hybrid laser arc welding (HLAW) of

closed circumferential welds. The process aims to

avoid weld imperfections in the overlap area of a

HLAW circumferential weld. A process control strategy

for closing the circumferential weld was developed

to achieve a defect-free overlap region by controlling

the solidification conditions at the end of the weld.

The controlled heat flow is achieved by adjusting the

parameters of both welding processes involved, the

laser beam as well as gas metal arc welding (GMAW)

process. Experimental investigations were carried

out on 12 mm to 15 mm thick tube sections. The influence

of process parameters such as the laser ramp

time, the change in magnification scale and the defocusing

of the laser beam on the solidification conditions

at the end of the circumferential weld was investigated

to find an optimum strategy for ramping out

the process energy. Within the framework of the experimental

studies, it was demonstrated that defocusing

the laser beam in the range between 60 mm and

100 mm over a short run-out area of the weld of approximately

15 mm led to a significantly better weld

formation in the overlap area. A favourable cupshaped

weld shape could be achieved without a tendency

to crack. The laser optics with a motor-driven

lens system made it possible to increase the laser

beam diameter without changing the position of the

GMAW arc relative to the component surface.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription