Investigation of the peculiarities of the formation of the weld beads on highly resistant steels during TIG and A-TIG welding – Part 1: Influences of the surface conditions of welded plates

Authors: Dr. Rustam M. Saidov, Dr.-Ing. Mario Kusch, Dr.-Ing. Kevin Hoefer, Fatima Rakhimova

DOI: https://doi.org/10.53192/WAC202202114

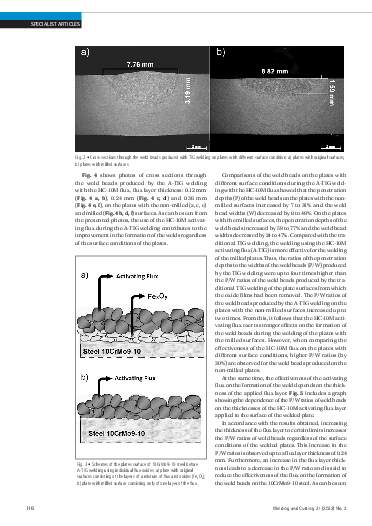

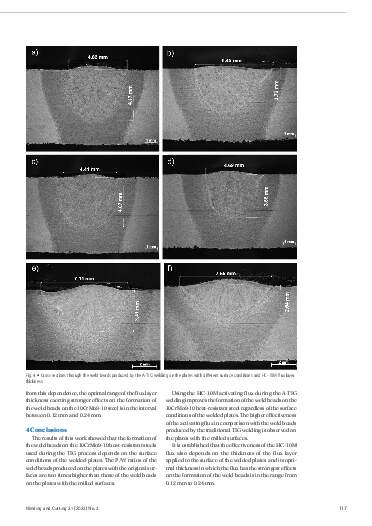

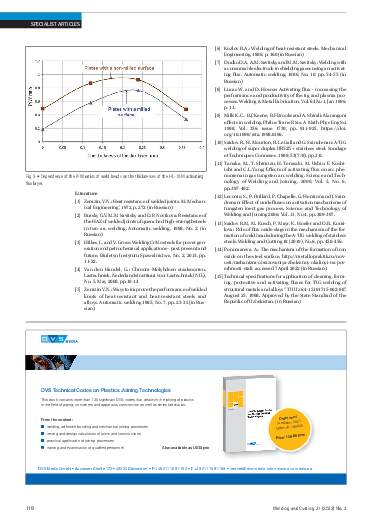

In this article (consisting of two parts), research has been carried out to study the features of the formation of the welded joints on heat-resistant steels using the example of the 10CrMo9-10 steel during the TIG and A-TIG welding with activating fluxes. Studies were also conducted into the effects of the surface conditions of the welded plates and the physical and chemical properties of activating fluxes on the features of the formation of the weld beads on the 10CrMo9-10 steel. This research has led to the development of recommendations for the compositions and properties of the activating fluxes for heat-resistant steels and a new high-performance flux which is intended for the A-TIG welding of these steels and increases the penetration capacity of the welding arc by 208% compared to the traditional TIG welding.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription