Effect of energy intensity on component quality through laser metal deposition (LMD) process

Authors: Prof. Dr.-Ing. Shahram Sheikhi, M. Sc. Eduard Mayer, M. Sc. Konstantin Bronstein

DOI: https://doi.org/10.53192/WAC202202120

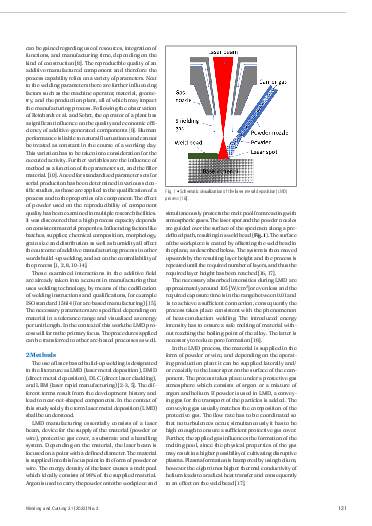

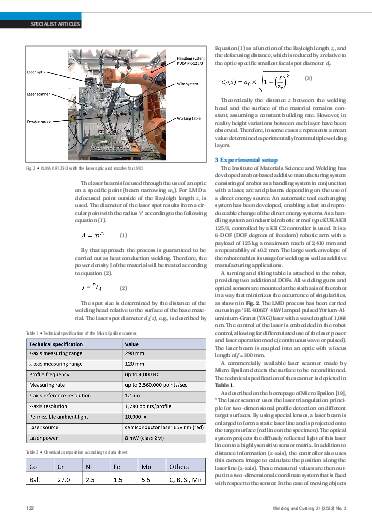

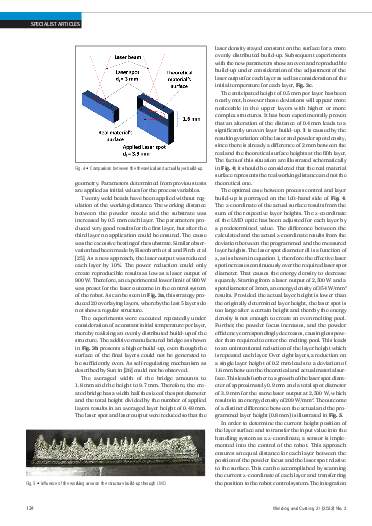

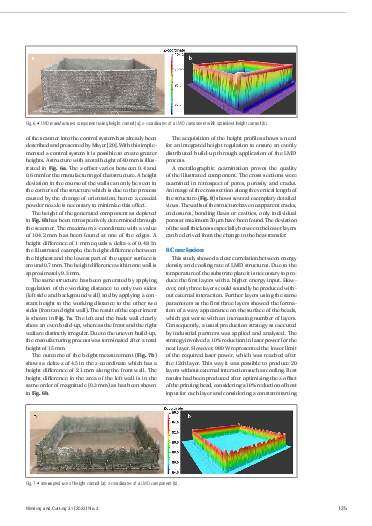

The ability to quickly produce complex structures of a unique design and with reduced waste are the main advantages of the additive manufacturing (AM) of metal-based components. Various AM processes are used in the industry and have been subject of research. Nevertheless, the correlation of energy input, heat balance and quality of components is still a point of research. This study will introduce an affordable method to control the height of each layer as a mechanism to assure the reproducibility of AM products. Moreover, the fundamentals of energy input and heat balance will be discussed in order to demonstrate that the general requirement for constant parameters as demanded by certification authorities actually increased the production time and reduced the quality of the parts. The research has been carried out by means of laser metal deposition with powder, which is one process of additive manufacturing for metal-based components.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription