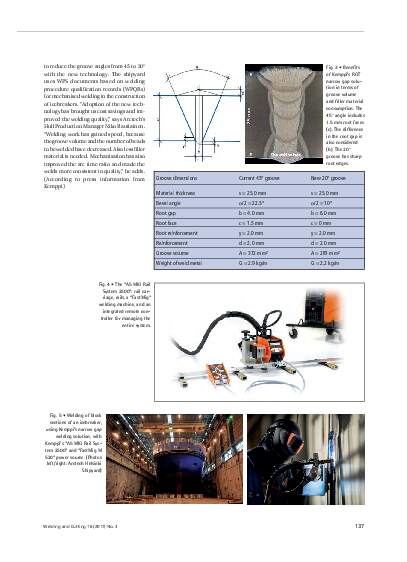

"Reduced Gap Technology" (RGT) challenges conventional joint design principles

In narrow gap welding, the groove angle

is typically less than 20° instead of the normal

45 to 60°. This decreases the number

of weld passes needed to complete the

joint, and it reduces the welding time and

the consumption of filler material. It also

makes the material less prone to distortion.

In other words, reducing the groove volume

has a multitude of positive effects on welding

quality, efficiency and productivity.

However, reducing the groove angle also

brings more challenges to welding. In a

narrow groove, the welding arc is difficult

to control. This may result in quality issues,

unless the user invests in welding torch and

accessories that are specially designed for

the application.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription