Material studies on additive welding of duplex and superduplex steel with controlled GMAW process (CMT)

Authors: Dr.-Ing. Manuela Zinke, Dr.-Ing. Benjamin Wittg, M. Sc. Juliane Stützer

DOI: https://doi.org/10.53192/WAC202204256

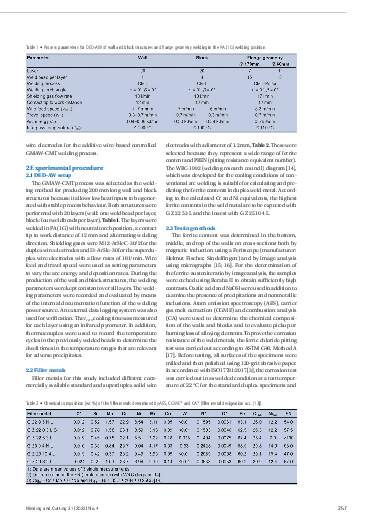

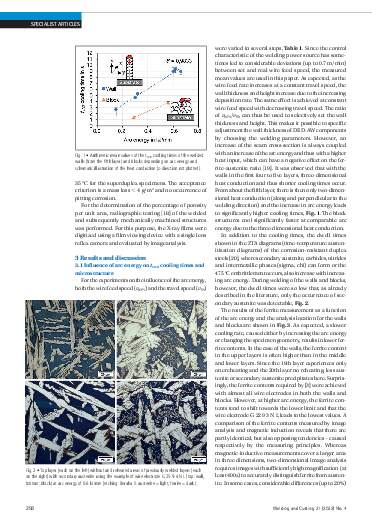

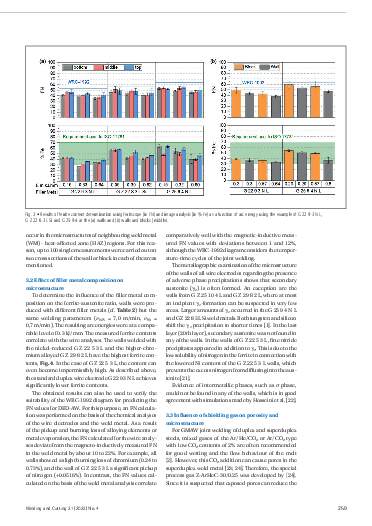

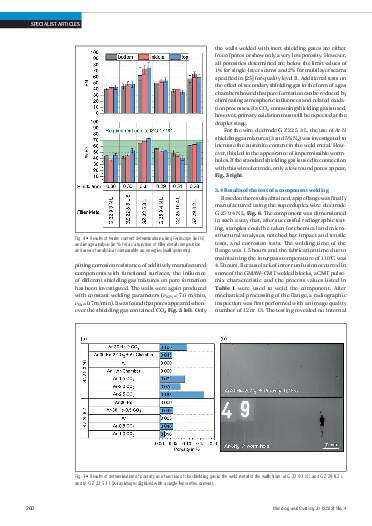

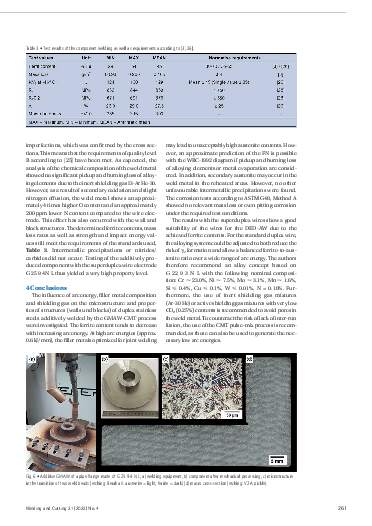

The article provides information on the influence of welding parameters, alloying systems and shielding gases on cooling times, microstructure and properties of additively manufactured thin-walled and block structures made of duplex and superduplex steel using the cold metal transfer (CMT) welding process, a process control variant of gas-shielded metal arc-welding (GMAW). The majority of the wire electrodes can be used for a weld metal with a required δ-ferrite content between 30 and 70% in the investigated arc energy range. If the arc energy input is too high, too much austenite may precipitate in the weld metal due to slow cooling. Here, the weld metal of the widely used duplex wire electrode G 22 9 3 N L is particularly susceptible. To provide a higher stability of balanced austenite-ferrite levels a model filler metal alloy for additive welding is recommended. Pore formation in duplex and superduplex weld metal is an additional challenge. This can be prevented by using inert shielding gases or shielding gases with considerably reduced CO2 levels.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription