Induction heating as practical preheating and post weld heat treatment to improve the quality in underwater wet welding of fi ne grain structural steels with high carbon equivalents

Authors: Dipl.-Ing. Jan Klett, Dr.-Ing. Oliver Brätz, Prof. Dr.-Ing. habil. Knuth-Michael Henkel, Dr.-Ing. Thomas Hassel

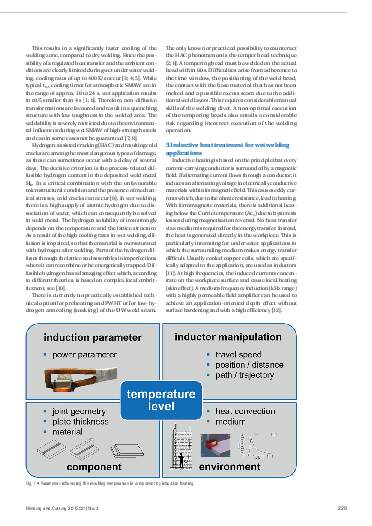

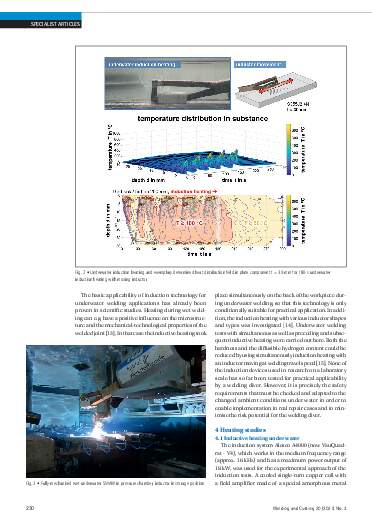

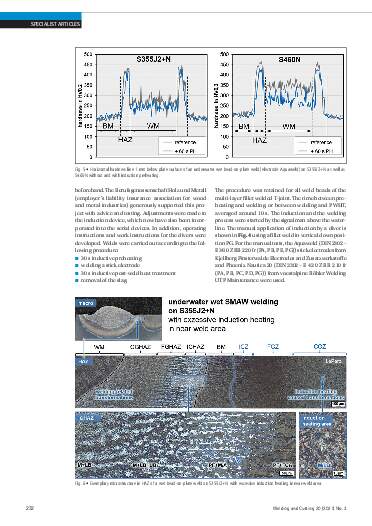

In this research project medium-frequency induction

technology was used for preheating and post-weld

heat treatment in underwater wet welding. After the

induction heating was successfully characterised,

both a reduction in the diffusible hydrogen content

and a decrease in hardness in the heat-affected zone

was demonstrated for wet welding application. In addition,

safety issues relating to the use of induction

technology in wet underwater welding were addressed

for the first time. Induction preheating and

post-weld heat treatment was successfully applied by

divers. A T-joint of steel grade S460N with a carbon

equivalent of 0.51% and thus causing a high susceptibility

to hydrogen-assisted cracking, was successfully

wet SMAW welded without cracks.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription