Expanded silicate in welding technology

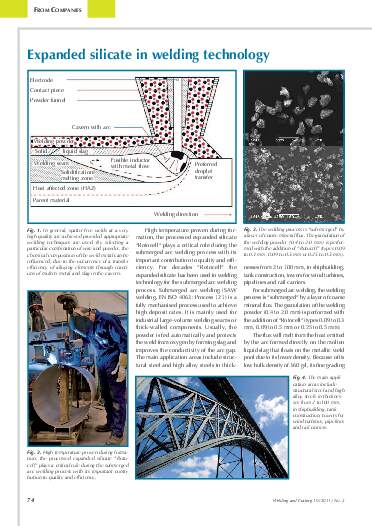

High temperature proven during formation,

the processed expanded silicate

“Rotocell“ plays a critical role during the

submerged arc welding process with its

important contribution to quality and efficiency.

For decades “Rotocell“ the

expanded silicate has been used in welding

technology for the submerged arc welding

process. Submerged arc welding (SAW

welding, EN ISO 4063: Process 121) is a

fully mechanised process used to achieve

high deposit rates. It is mainly used for

industrial large-volume welding seams or

thick-walled components. Usually, the

powder is fed automatically and protects

the weld from oxygen by forming slag and

improves the conductivity of the arc gap.

The main application areas include structural

steel and high alloy steels in thicknesses from 2 to 100 mm, in shipbuilding,

tank construction, towers for wind turbines,

pipelines and rail carriers.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription