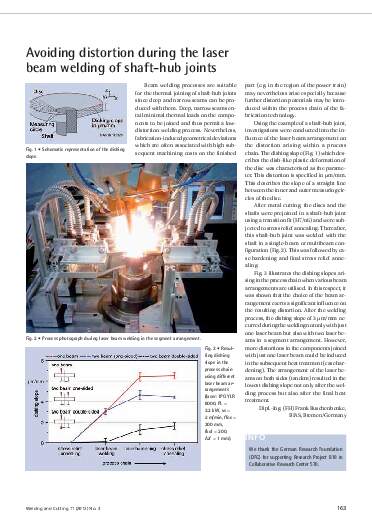

Avoiding distortion during the laser beam welding of shaft-hub joints

Beam welding processes are suitable

for the thermal joining of shaft-hub joints

since deep and narrow seams can be produced

with them. Deep, narrow seams entail

minimal thermal loads on the components

to be joined and thus permit a lowdistortion

welding process. Nevertheless,

fabrication-induced geometrical deviations

which are often associated with high subsequent

machining costs on the finished part (e.g. in the region of the power train)

may nevertheless arise especially because

further distortion potentials may be introduced

within the process chain of the fabrication

technology.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription