Approaches for a better understanding of the formation and reduction of welding fumes in GMA welding under consideration of innovative welding processes

Author: Dr.-Ing. Sascha Rose

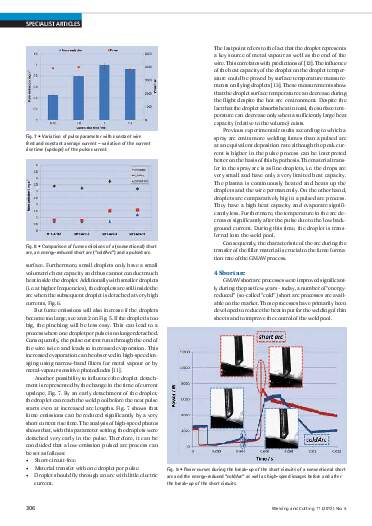

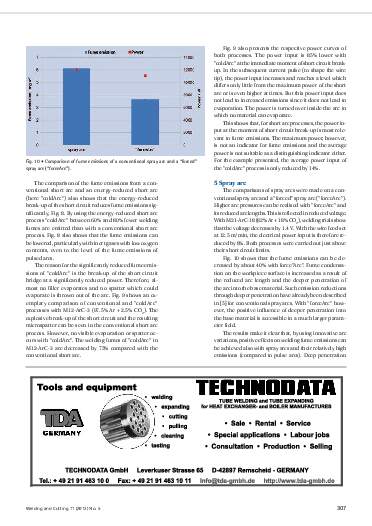

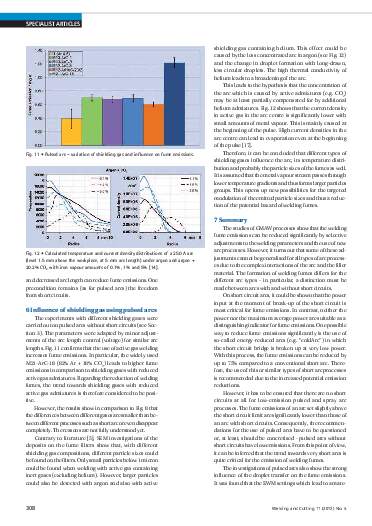

GMAW processes are of very great economic importance in mechanised

and automated production. Despite the great technical advancements during

the last years, the acceptance of the process suffers from high emissions,

particularly from welding fumes. Welding fumes are airborne particles

which mainly consist of metal oxides. Moreover, radiation and gases are

emitted. The exposure of welders and operators to fumes and gases is currently

reduced by extraction systems, extraction torches and breathing

masks. Although the arc process is the source of emission, the process

itself has not been developed specifically with regard to low fume formation

rates until now. As basic research for future low-emission GMAW processes,

investigations into the formation mechanisms of welding fumes were carried

out in the EWM Award “Physics of Welding“. Despite the variety of

fume measurements in the past, the causal mechanisms are not fully understood

yet. Only with the understanding of these mechanisms can effective

strategies be derived to counteract the formation of emissions and to

reduce the hazard potential of the process. In the first place, investigations

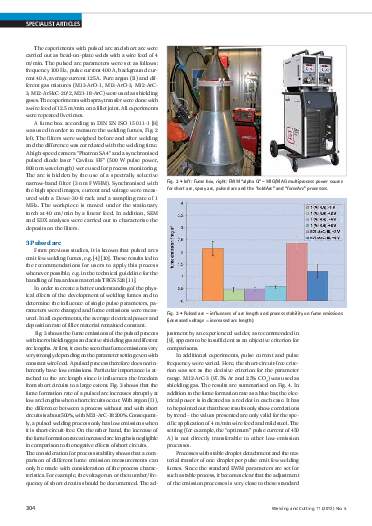

were carried out into pulsed processes which are known to emit few welding

fumes. The pulsed arc offers many adjustable process parameters in comparison

to short arcs and spray arcs. Subsequently, experiments with conventional

and modified (reduced-energy) short arcs as well as experiments

with conventional and modified (forced) spray arcs were carried out in

order to investigate the potential of modern variants for reducing welding

fume emissions. The results show that the fume emissions of GMAW

processes and therefore the hazard potential for welders and operators

can be reduced significantly.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription