Additive manufacturing using selective electron beam melting

Authors: Dr.-Ing. Matthias Markl, Dr.-Ing. Matthias Lodes, Dr.-Ing. Martin Franke, Prof. Dr.-Ing. habil. Carolin Körner

Additive manufacturing encompasses all the procedures

which build up a component layer by layer on

the basis of a three-dimensional computer model. Additive

building-up permits complex geometrical shapes

which are subject to hardly any restrictions and thus

could not be implemented with conventional manufacturing

procedures or only at great expense. Similar

to selective laser beam melting, selective electron beam

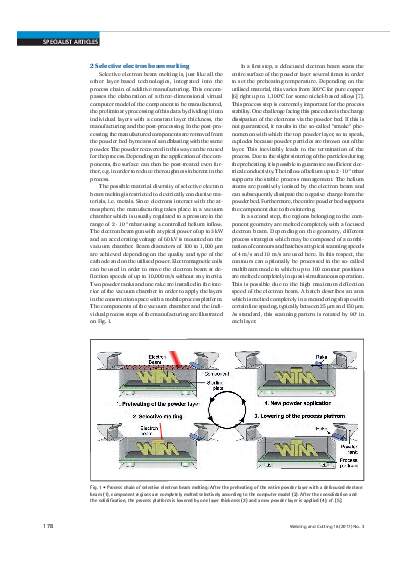

melting (SEBM) is a powder-bed-based additive manu -

facturing process in which the powder particles are locally

melted completely and consolidated by the beam.

The electron beam permits the processing of high-melting

and reactive metals in a vacuum as well as a high

construction rate for additive manufacturing processes

due to high power densities and quick deflection

speeds. This article not only describes the installation

setup and the process sequence during SEBM but also

introduces the material classes investigated until now,

selected applications and the numerical simulation of

this procedure.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription